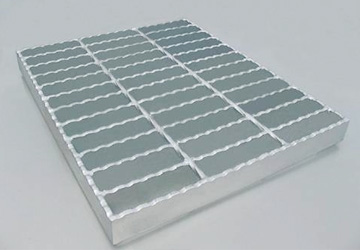

Metal Bar Grating is the workhorse of the industrial flooring market and has served industry for decades.Strong and durable with an exceptional strength-to-weight ratio, metal bar grating can be easily fabricated to nearly any configuration.The high percentage of open area makes bar grating practically maintenance-free and all products are fully recyclable.

Manufactured by assembling a series of equally spaced metal bars to connecting cross members, bar grating is available in three popular materials; mild carbon steel, 6000 series aluminum, and 300 series stainless steels. Additionally, Grating Pacific has the capacity to produce gratings constructed with other specialty metal alloys.

Manufacturing Methods

WELDED GRATING

Economical design ideal for most industrial applications. Manufactured by welding the bearing bar/cross bar intersection, typically with automated forge welding equipment. Available in carbon steel and stainless steel.

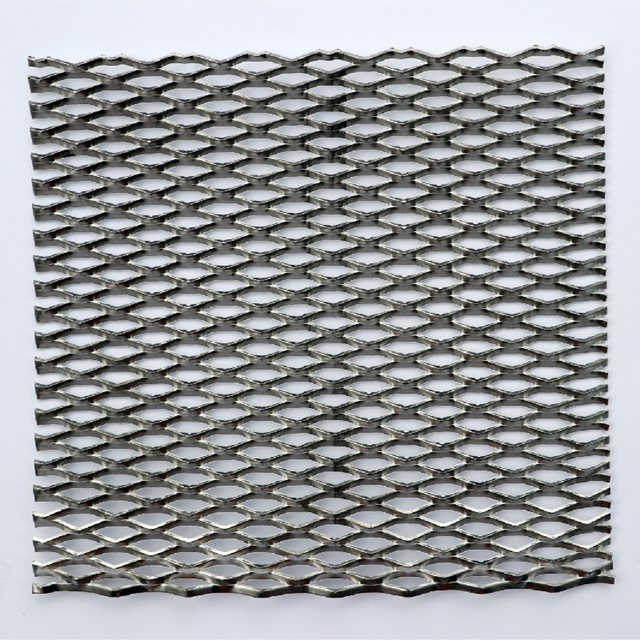

DOVETAIL PRESSURE LOCKED

Popular for the manufacture of aluminum, stainless steel, and close mesh gratings. Cross bars are inserted into pre-punched holes in the bearing bars and hydraulically deformed to lock the bars in place.

SWAGED PRESSURE LOCKED

Assembled by inserting pre-punched bearing and cross bars into an “eggcrate” configuration and deforming the cross bars under intense hydraulic pressure. Available in all materials and ideal for architectural and ornamental applications.

RIVETED GRATING

Exceptionally durable grating manufactured by riveting bearing bars and bent connecting bars at their contact points. Excellent for applications involving impact loads and repetitive traffic patterns.

Bar grating

APPLICATION

Bar grating