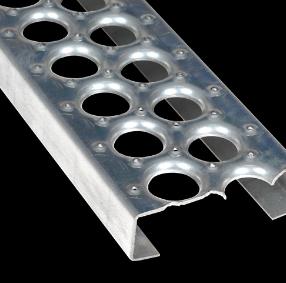

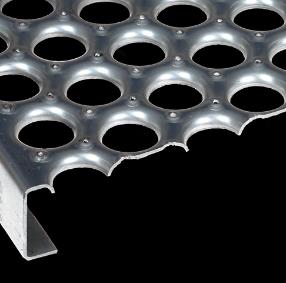

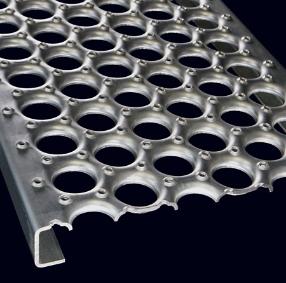

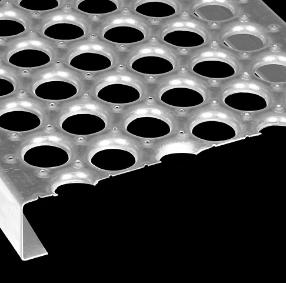

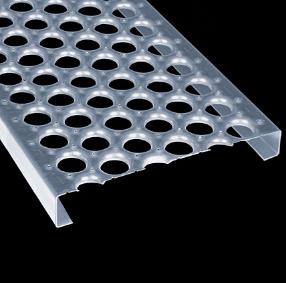

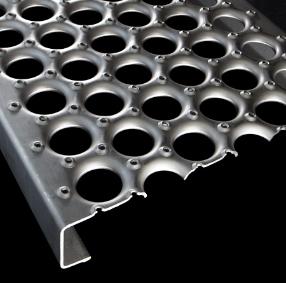

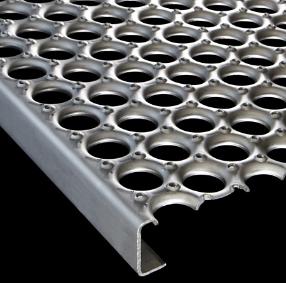

Perf-O Grip™safety grating and stair treads from Yunde Metals are used to create non-slip commercial and industrial metal floor grating for walkways, stairways, stair treads, and steel flooring. Perf-O Grip™ metal stair treads have a high load capacity, are durable, and have a high strength-to-weight performance. The Perf-O Grip™ metal grating stair treads can be used in a variety of environments, for many different applications. This metal grating is manufactured with welded end carrier plates. The metal stair treads are also pre-punched with holes, which allows the safety treads to be bolted to the stair stringers.

Benefits of Perf-O Grip™ Safety Metal Grating and Stair Treads:

Embossed traction buttons on the metal floor grating and stair treads provide superior slip resistance in all directions and in all weather conditions

Large debossed holes on metal grating and stair treads provide maximum drainage of debris and allow for up to 50% free air opening depending on the panel width

One-piece metal construction

Lightweight design of metal grating and stair treads provides high strength-to-weight ratio

Perf-O Grip™ safety grating is designed for a long floor grating life span with little maintenance for industrial walkways and stairs. In fact, our safety grating and stair treads are self-cleaning due to the resilience of the walking surface. Not only is Perf-O Grip™ safety grating low maintenance, it is also a simple and economical installation. Since metal grating planks are self-framing the installation process is quick and easy.

Yunde Metals offers custom fabrication services for our Perf-O Grip™ safety grating. Since this type of metal grating is highly adaptable, it can be used in cost effective custom metal fabrication processes. Perf-O Grip™ metal grating can be easily formed in a standard channel or custom shapes. Our channel depths include:

1-1/2 inch

2 inches

3 inches

4 inches

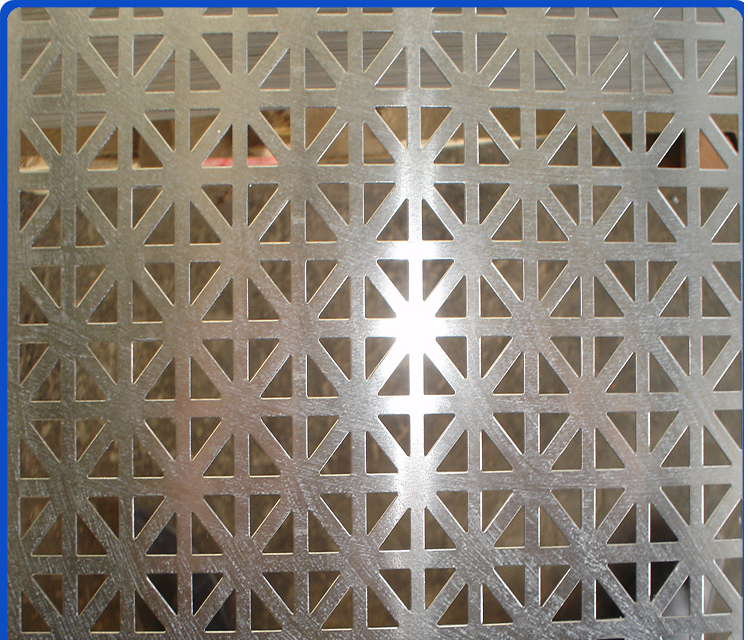

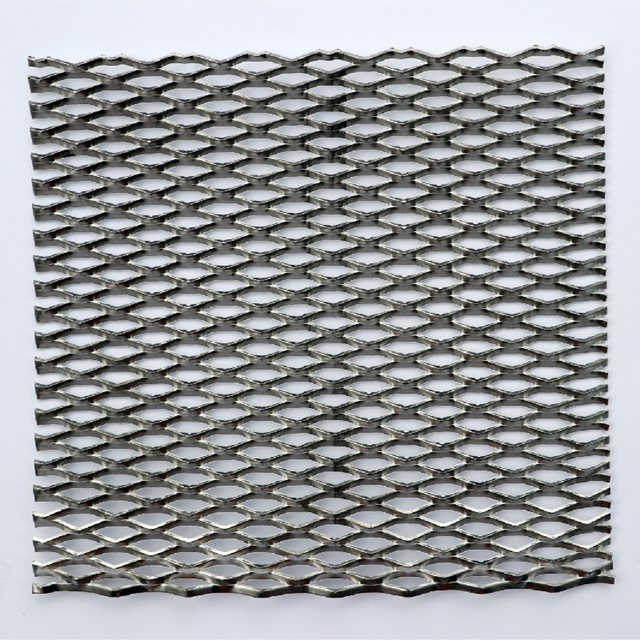

| Perf-O Grip | Aluminum | Galvanized | Carbon Steel | |||||||||||||

| Gauge | Gauge | Gauge | ||||||||||||||

| Opening type | depth | 9 | 10 | 11 | 13 | 14 | 16 | 9 | 10 | 11 | 12 | 14 | 9 | 10 | 12 | 14 |

| 2-Diamond | 1-/2″ | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 3″ | ● | ● | ● | ● | ● | |||||||||||

| 4″ | ● | ● | ● | ● | ||||||||||||

| 5-Diamond | 1-1/2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 3″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 4″ | ● | ● | ● | ● | ||||||||||||

| 6-Diamond | 1-1/2″ | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 3″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| 4″ | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 10-Diamond | 1-1/2″ | ● | ● | ● | ● | ● | ||||||||||

| 2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 3″ | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 4″ | ● | ● | ● | ● | ● | ● | ||||||||||

| 13-Diamond | 1-1/2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 2″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 3″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 4″ | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||