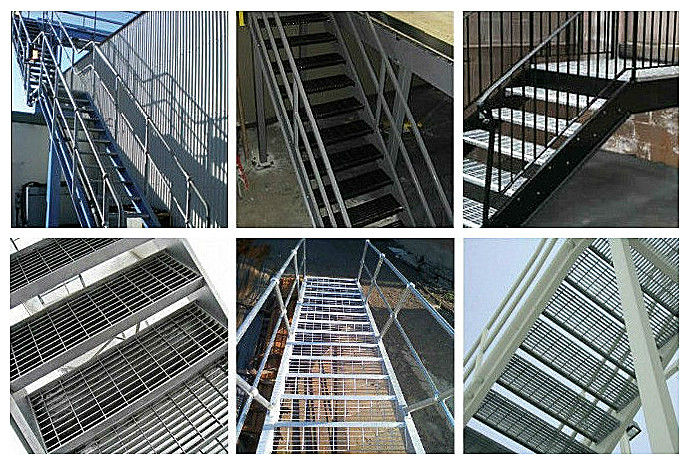

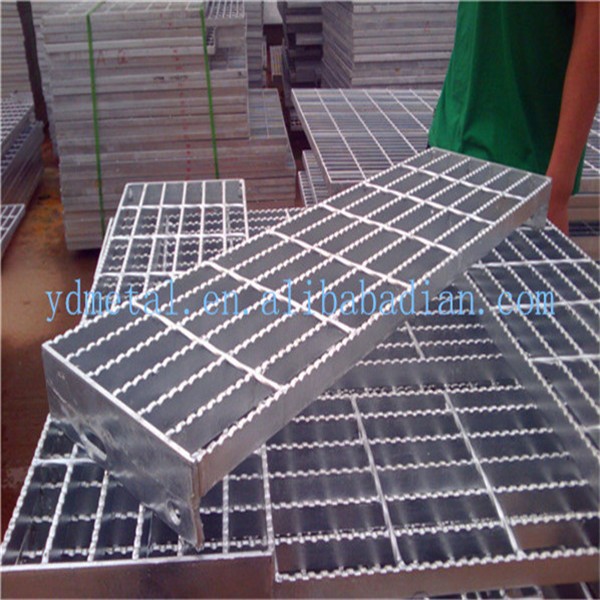

Hot dip galvanized serrated flat bar steel grating with twisted square rod for stairs and treads

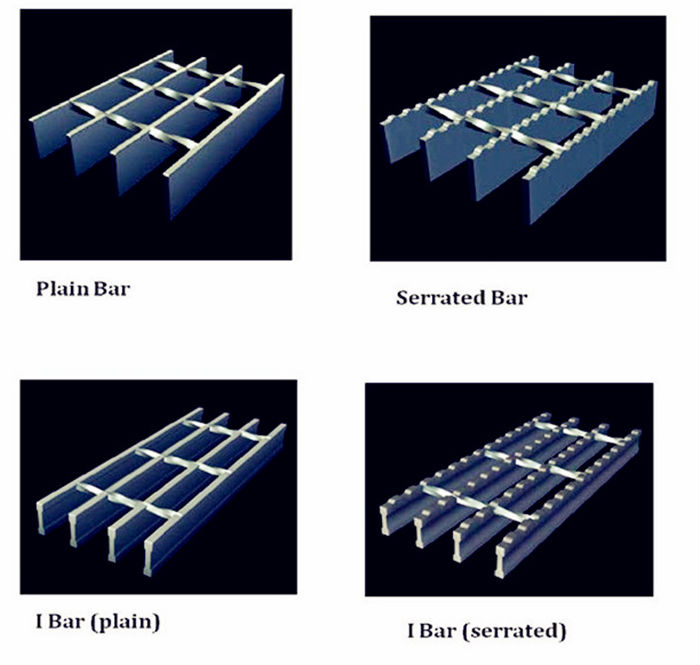

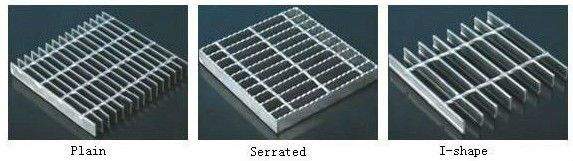

1.The shape of bearing bar: Plain type (may be omitted in the symbol of steel grating), Serrated type and I-Shape type

2.Bearing bar pitches can be 12.5, 15, 20, 30, 30.16, 32.5, 34.3, 40, 60mm, of which 30mm & 40mmare recommended.

3.Cross bar pitches can be 38, 50, 60,100mm, of which 50mm & 100mm are recommended.

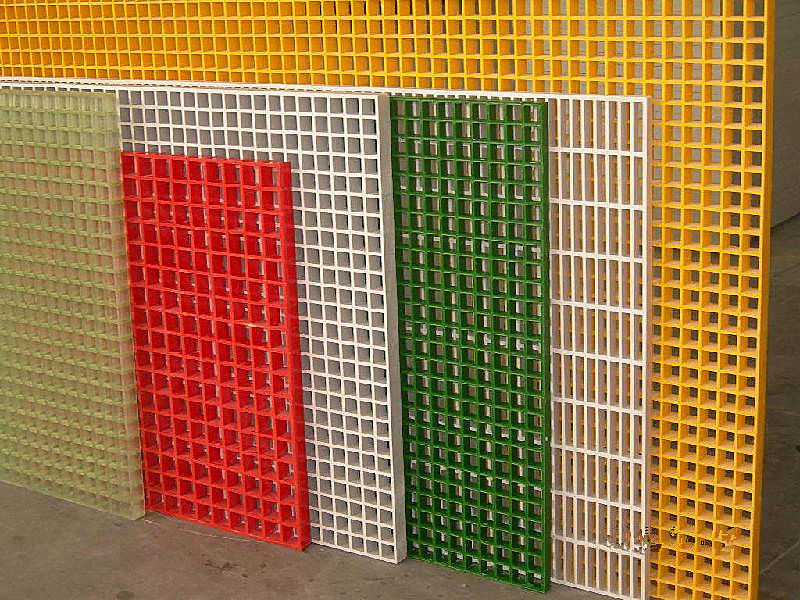

4.Surface treatment: Hot-dip galvanizing, paint or other anti-corrosive coatings are available, of which hot-dip galvanizing is generally recommended.

Material: Q235 in line with GB/T700 steel

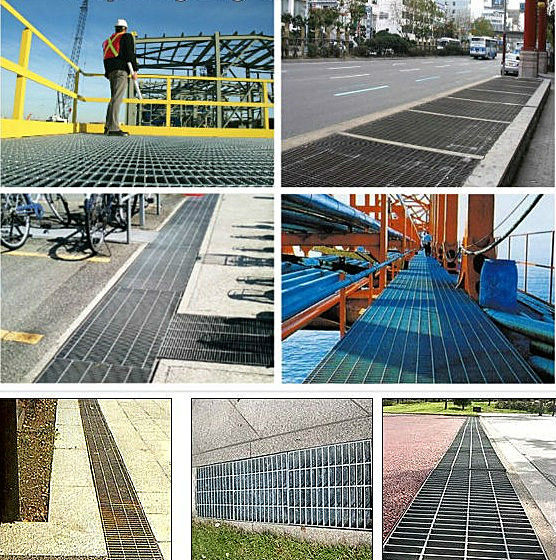

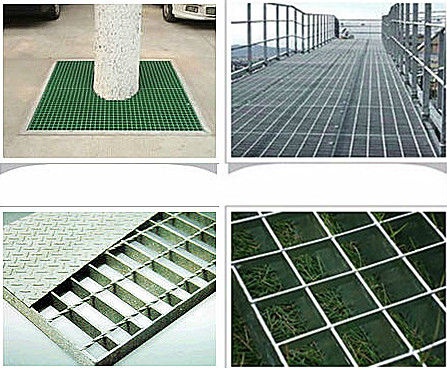

Application: flooring, catwalk, mezzanines/decking, stair tread, fencing, ramp, dock, trench cover, drainage pit cover, maintenance platform, pedestrian/crowded pedestrian, factory, workshop, motor rooms, trolley channel, heavy loading area, boiler equipment and heavy equipment area, etc

Tolerance :

The allowed deviation of length is +0/-5mm, while the allowed deviation of width is +/-5 mm.

The non-perpendicularity of bearing bar is allowed no more than 10% of width of bearing bar.

Cross bar surface should not surpass bearing bar surface 1mm, beginning & end of cross bar should not surpass the end surfaces of two sides of grating 2mm.

Standards:

| Steel grating standard | Steel standard | Galvanizing standard | |

| China standard | YB/T 4001.1-2007 | GB700-88 | GB/T13912-2002 |

| USA standard | ANSI/NAAMM(MBG531) | ASTM(A36) | ASTM(A123) |

| U.K. standard | BS4592 | BS4360(43A) | BS729 |

| Australia standard | AS1657 | AS3679 | AS1650 |

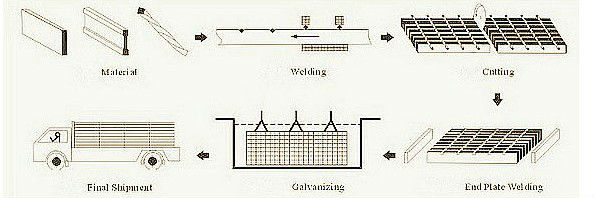

Manufacturing process of steel grating:

Material-welding-cutting-end plate welding-surface treatment-final shipment